JIVA was started in 1998 by Sharmila Dalmia as a small set-up in the basement of her home but with the vision to become a leading garment manufacturer and exporter. Today the company has grown to have 3 factories with a manufacturing area of 200,000 sq ft, 1,000+ sewing machines, and a workforce of 2,000+ people.

JIVA is inherently a design-driven company that prides itself on its strength in technique engineering and expertise in all kinds of embellishments. However, over time, we have been able to capitalize on our advanced planning and monitoring systems and stringent quality control standards to become an “all-in-one solution” for our customers – we execute orders of all volumes, from 500 pcs to 500,000+ pcs, and all types, from high fashion tops and dresses to basic sleepwear and kids wear to sweaters.

JIVA operates 2 cut-to-pack production facilities and has a monthly capacity of 275,000 pcs.

Each facility is equipped with stateof-the-art machinery and a modern set up that enables the company to produce high quality garments and set a benchmark in the industry.

JIVA has 1000+ sewing machines including sleeve attach, blind stitch, eyelet kaj and advanced folders and UBT machines

We produce a large volume basic cut-andsew wovens and knits which highlight fabric quality, and efficient workmanship. These products are not only competitively priced but also available with faster lead times.

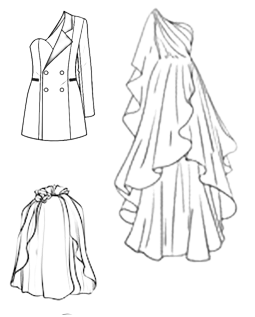

We are known for our high-fashion products, which feature multi-process garments with computer and hand embroideries, laces, stitching detailing, embellishments, and special fabrics and garment treatments

JIVA’s has a strong foothold in fabrics including cotton, linen, rayon, modal, lyocell, tencel, silk, polyester and blends — from lightweight tops fabric to heavy-weight jackets fabric.

Understanding the importance of a strong supplier base, JIVA has devoted great effort to building alliances with some of the most reliable manufacturers globally.

In addition to sourcing fabric from different regions in India, we import yarns and fabrics from across Asia, working closely with suppliers in China and Korea

Understanding the importance of a strong supplier base, JIVA has devoted great effort to building alliances with some of the most reliable manufacturers globally.

In addition to sourcing fabric from different regions in India, we import yarns and fabrics from across Asia, working closely with suppliers in China and Korea

We have a strong design and product development team with expertise in CAD, textile innovation, and apparel design. Wellversed with global fashion trends, our designers create collections based on customer taste and mood boards. ~40% of our turnover is derived from our in-house designs.

We have three computer embroidery machines in-house along with a reliable network of compliant embroidery vendors for bulk production. We also have the capacity to accommodate 100+ hand embroidery artisans in-house.

Our centralized production planning team is responsible for planning and refining stitching line plans, optimizing manufacturing costs and capacity, streamlining production processes, monitoring production output against targets and ensuring that shipments are delivered on time.

We have stringent quality standards and follow a multi-tier quality control and audit system, with each account having a dedicated quality representative, who is involved in quality control at all stages of raw material checking and production.

In 2022, JIVA invested in 50+ the best-in-class German technology Stoll multi-gauge knitting machines with a wide gauge capacity ranging from 4gg to 14gg.

We can knit a variety of yarns and blends such as:

We can make a variety of basic and complex knitting designs structures including cables, jacquards, pointelles (which can be used as a alternatives for hand crochet), intarsia designs with 4 colors insertion, etc. We can add lycra depending on the knitting structure.